When I had finished constructing my IP Engineering plate frame Simplex loco (see How I constructed an IP Engineering plate frame Simplex) and equipped it with Deltang radio control, I decided she ought to have a simple sound system. Owing to its diminutive size, the MyLocoSound card and even the Mtronics soundcards were going to be too large; I needed something ultra small and, being a skinflint, something ultra cheap.

On a whim, I sent for a very cheap sound module (£1.29 inc postage) which was intended to be used for musical greetings cards. This came equipped with a 'play' button, a 'record' button, an LED, a microphone and a speaker in addition to the board itself and a couple of small batteries.

The first job was to track down a suitable sound effect. Fortunately, I had shot some video of Simplexes (Simplices??), at the Apedale Valley Light Railway, and so was able to record the sound of one ticking over by placing the mike near the speaker on my laptop and holding down the record button until the LED flashed to show it had reached its full 10 second limit.

I needed to do the recording a couple of times until I was happy with the result. Not exactly high fidelity, but the sound is just about recognisable.

After removing the blobs of hot glue from the board to get at the connections, ......

..... by prising them off with a finger nail, ......

.... the next job was to find a way of making the recording loop continuously. Some research on the internet revealed this was possible and so I experimented by touching the end of a lead soldered to the Play button connection on the board to various contacts on the board until I found the right spot. This turned out, for some reason, to be the terminals for the microphone. Once I'd satisfied myself that this worked, a lead was soldered permanently from the play button connection on the board to one of the mike terminals.

There is a pause of roughly 0.5 seconds at the end of each 10 second cycle. I've not yet found a way of overcoming this. I could try synching two boards to work in unision but slightly out of step, or find a sound effect which has a distinct engine beat and try to coincide the pause with the rhythm of the engine. However, for now, I am prepared to live with this slight anomaly.

Once, I was satisfied with the sound, I unsoldered the leads for the mike, the LED and record button, leaving the leads for the Play Button and the speaker still connected.

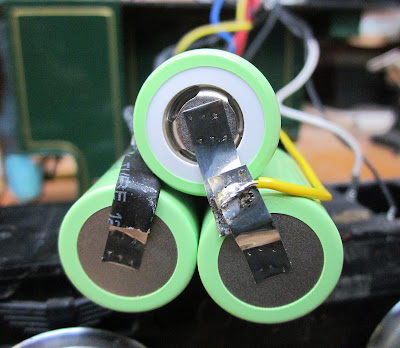

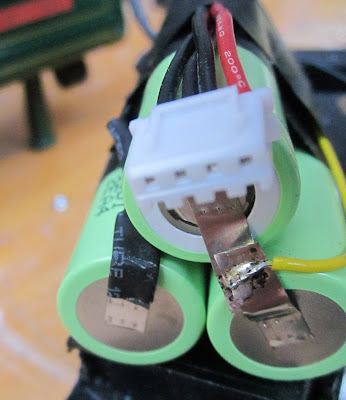

I then turned the board over and unbent the tags holding the batteries to the board.

I then carefully unsoldered the metal cradles for the batteries.

Ith a craft knife, I carefully scored across the board to separate the section of the circuit board holding the batteries from the rest of the board and snapped it off.

Two wires were then soldered to the tracks on the circuit board leading from the batteries.

As the Simplex was powered with a single 3.7 volt li-ion battery, I checked that this would be a sufficient for the board. The leads were connected to the negative supply from the loco battery and to the output side of the power switch. This supply proved sufficient to power the board (confirmed by pressing the 'Play' button.

When I install boards in my 12v powered locos, I will need to use a voltage regulator circuit such as this to limit the supply voltage for the board (see below).

I decided to replace the loudspeaker supplied with the module for one slightly smaller in diameter to enable it to be fitted under the cab roof. A small speaker was purchased from Maplin (Part code N93FU ). The 'Play' button was also positioned under the cab roof, so the loco could be run with or without sound.

The circuit board fitted quite neatly under the engine cover of the Simplex, being held in place with a blob of Blutak.

As indicated above, for now I am happy to live with the hiccup in the sound, though may experiment with ways of overcoming it.

I have also added another sound module to the Simplex containing a klaxon sound. As the sound does not need to loop, there was no need to solder the lead from the play button connection to the mike connection. The klaxon sound board is triggered by the output from the C output pad on my Deltang Rx65b receiver/controller, responding when the bind button is pressed on my Deltang Tx22 transmitter.

As you can see from the video. The klaxon sound is quite clear when the engine sound is not running, but is somewhat muffled by the engine sound. This is probably because both boards are connected to the same speaker. I will try experimenting with adding low value resistors into the circuit between the boards and the speaker to see if I can balance the outputs. If I had more space, the klaxon board would have its own speaker.

On a whim, I sent for a very cheap sound module (£1.29 inc postage) which was intended to be used for musical greetings cards. This came equipped with a 'play' button, a 'record' button, an LED, a microphone and a speaker in addition to the board itself and a couple of small batteries.

The first job was to track down a suitable sound effect. Fortunately, I had shot some video of Simplexes (Simplices??), at the Apedale Valley Light Railway, and so was able to record the sound of one ticking over by placing the mike near the speaker on my laptop and holding down the record button until the LED flashed to show it had reached its full 10 second limit.

I needed to do the recording a couple of times until I was happy with the result. Not exactly high fidelity, but the sound is just about recognisable.

After removing the blobs of hot glue from the board to get at the connections, ......

..... by prising them off with a finger nail, ......

.... the next job was to find a way of making the recording loop continuously. Some research on the internet revealed this was possible and so I experimented by touching the end of a lead soldered to the Play button connection on the board to various contacts on the board until I found the right spot. This turned out, for some reason, to be the terminals for the microphone. Once I'd satisfied myself that this worked, a lead was soldered permanently from the play button connection on the board to one of the mike terminals.

There is a pause of roughly 0.5 seconds at the end of each 10 second cycle. I've not yet found a way of overcoming this. I could try synching two boards to work in unision but slightly out of step, or find a sound effect which has a distinct engine beat and try to coincide the pause with the rhythm of the engine. However, for now, I am prepared to live with this slight anomaly.

Once, I was satisfied with the sound, I unsoldered the leads for the mike, the LED and record button, leaving the leads for the Play Button and the speaker still connected.

I then turned the board over and unbent the tags holding the batteries to the board.

I then carefully unsoldered the metal cradles for the batteries.

Ith a craft knife, I carefully scored across the board to separate the section of the circuit board holding the batteries from the rest of the board and snapped it off.

Two wires were then soldered to the tracks on the circuit board leading from the batteries.

As the Simplex was powered with a single 3.7 volt li-ion battery, I checked that this would be a sufficient for the board. The leads were connected to the negative supply from the loco battery and to the output side of the power switch. This supply proved sufficient to power the board (confirmed by pressing the 'Play' button.

When I install boards in my 12v powered locos, I will need to use a voltage regulator circuit such as this to limit the supply voltage for the board (see below).

I decided to replace the loudspeaker supplied with the module for one slightly smaller in diameter to enable it to be fitted under the cab roof. A small speaker was purchased from Maplin (Part code N93FU ). The 'Play' button was also positioned under the cab roof, so the loco could be run with or without sound.

The circuit board fitted quite neatly under the engine cover of the Simplex, being held in place with a blob of Blutak.

As indicated above, for now I am happy to live with the hiccup in the sound, though may experiment with ways of overcoming it.

I have also added another sound module to the Simplex containing a klaxon sound. As the sound does not need to loop, there was no need to solder the lead from the play button connection to the mike connection. The klaxon sound board is triggered by the output from the C output pad on my Deltang Rx65b receiver/controller, responding when the bind button is pressed on my Deltang Tx22 transmitter.

As you can see from the video. The klaxon sound is quite clear when the engine sound is not running, but is somewhat muffled by the engine sound. This is probably because both boards are connected to the same speaker. I will try experimenting with adding low value resistors into the circuit between the boards and the speaker to see if I can balance the outputs. If I had more space, the klaxon board would have its own speaker.

As indicated above. I am intending to install a couple of these boards into another of my small diesel locos which is powered by a higher voltage battery pack. I will need to use a voltage regulator circuit to reduce the voltage for the sound board, but there might be space in the second diesel for two loudspeakers.

I might also experiment with ways of overcoming the half second hiccup at the end of the looped recording .

To be continued ........